实例介绍

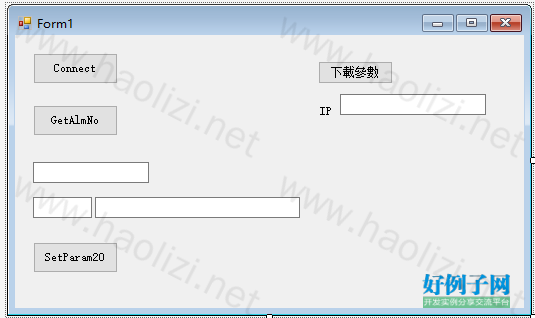

【实例简介】Fanuc CNC data image

【实例截图】

【核心代码】

using System;

using System.Collections.Generic;

using System.ComponentModel;

using System.Data;

using System.Drawing;

using System.Text;

using System.Windows.Forms;

//using Focas1;

namespace GetAlmMsg

{

public partial class Form1 : Form

{

ushort cncHandle = 0;

private short preState = 0;

private Focas1.ODBST cncStatus = new Focas1.ODBST();

private Focas1.ODBAHIS alarmHis = new Focas1.ODBAHIS();

public Form1()

{

InitializeComponent();

}

private void btnConnect_Click(object sender, EventArgs e)

{

try

{

Focas1.focas_ret ret = (Focas1.focas_ret)Focas1.cnc_allclibhndl3("192.168.0.31", 8193, 5, out cncHandle); //眔library handle

//Focas1.focas_ret ret = (Focas1.focas_ret)Focas1.cnc_allclibhndl3(textBox_IP.Text, 8193, 5, out cncHandle); //眔library handle

//textBox_IP

if (ret != Focas1.focas_ret.EW_OK)

{

this.rdpara.Enabled = false;

throw new Exception("Can't connect to CNC controller!");

}

else

{

this.rdpara.Enabled = true;

btnConnect.Enabled = false;

}

}

catch (Exception ex)

{

MessageBox.Show(ex.Message, "Message");

}

}

private void butGetAlmNo_Click(object sender, EventArgs e)

{

DoAlmRecord(false);

//short almNo = 0;

//string almDate = "";

//string almMsg = "";

//almMsg = GetAlarmMessage(ref almNo, ref almDate);

//textBox1.Text = almDate;

//textBox2.Text = almNo.ToString();

//textBox3.Text = almMsg;

//DoAlmRecord(true);

}

private void Form1_FormClosed(object sender, FormClosedEventArgs e)

{

if ( cncHandle != 0 )

Focas1.cnc_freelibhndl(cncHandle);

}

private void AlmTimer1_Tick(object sender, EventArgs e)

{

Focas1.cnc_statinfo(cncHandle, cncStatus);

//Record the start time of Alarm

if ( cncStatus.alarm==1 && preState==0 )

{

DoAlmRecord(false);

short almNo = 0;

string almStartTime = "";

string almMsg = "";

almMsg = GetAlarmMessage(ref almNo, ref almStartTime);

textBox1.Text = almStartTime;

textBox2.Text = almNo.ToString();

textBox3.Text = almMsg;

DoAlmRecord(true);

}

//Record the end time of Alarm

if ( cncStatus.alarm==0 && preState==1 )

{

DoAlmRecord(false);

//short almNo = 0;

//string buf = "";

//string almMsg = "";

string almEndTime = "";

DateTime almTime = DateTime.Now;

//almMsg = GetAlarmMessage(ref almNo, ref buf);

almEndTime = almTime.Year.ToString("D4")

almTime.Month.ToString("D2")

almTime.Day.ToString("D2")

almTime.Hour.ToString("D2")

almTime.Minute.ToString("D2")

almTime.Second.ToString("D2");

textBox1.Text = almEndTime;

//textBox2.Text = almNo.ToString();

//textBox3.Text = almMsg;

DoAlmRecord(true);

}

preState = cncStatus.alarm;

}

public void DoAlmRecord(bool flag)

{

short ret = -1;

if (flag == false)

ret = Focas1.cnc_stopophis(cncHandle);

else

ret = Focas1.cnc_startophis(cncHandle);

}

public string GetAlarmMessage(ref short almNo, ref string almTime)

{

ushort almCount = 0;

Focas1.cnc_rdalmhisno(cncHandle, out almCount);

ushort sNum = almCount;

ushort eNum = almCount;

ushort len = (ushort)(6 48 * (eNum - sNum 1));

Focas1.cnc_rdalmhistry(cncHandle, sNum, eNum, len, alarmHis);

almNo = alarmHis.alm_his.data1.alm_no;

almTime = String.Format("{0:00}", alarmHis.alm_his.data1.year 2000)

String.Format("{0:00}", alarmHis.alm_his.data1.month)

String.Format("{0:00}", alarmHis.alm_his.data1.day)

String.Format("{0:00}", alarmHis.alm_his.data1.hour)

String.Format("{0:00}", alarmHis.alm_his.data1.minute)

String.Format("{0:00}", alarmHis.alm_his.data1.second);

return alarmHis.alm_his.data1.alm_msg;

}

public Focas1.IODBPSD_1 prmDataNoAxis = new Focas1.IODBPSD_1();

public Focas1.IODBPSD_3 prmData = new Focas1.IODBPSD_3();

private void btnSetParam_Click(object sender, EventArgs e)

{

short len = 0;

short prmNum = 20;

//short type = 25;//11001

//byte[] val = new byte[3] {1,2,3};

byte value = 5;

//if((type & 4) == 0)

//{

len=4 1;//datano(2 bytes) type(2 bytes) cdata(1 byte)

//prmData.datano = prmNum;

//prmData.type = type;

prmDataNoAxis.datano = prmNum;

prmDataNoAxis.type = 0;//No axis

//if ((type & 3) == 1)

//{

//for (int i = 0; i < 3; i )

// prmData.cdatas[i] = val[i];

prmDataNoAxis.cdata = value;

//}

//Focas1.focas_ret ret = (Focas1.focas_ret)Focas1.cnc_wrparam(cncHandle, len, prmData);

Focas1.focas_ret ret = (Focas1.focas_ret)Focas1.cnc_wrparam(cncHandle, len, prmDataNoAxis);

if (ret == Focas1.focas_ret.EW_OK)

btnSetParam.Enabled = false;

//}

}

private void rdpara_Click(object sender, EventArgs e)

{

short ret, idx, axno;

short start = 1, end1 = 1000, axno1 = -1, length = 10000;

Focas1.ODBSYS info = new Focas1.ODBSYS();

Focas1.IODBPSD_1 param = new Focas1.IODBPSD_1();

Focas1.IODBPSD_3 param1 = new Focas1.IODBPSD_3();

Focas1.ODBPARANUM paranum = new Focas1.ODBPARANUM();

ret = Focas1.cnc_rdparanum(cncHandle, paranum);

//start = (short)(paranum.para_min 1);

//end1 = (short)paranum.total_no;

ret = Focas1.cnc_rdparar(cncHandle, ref start, end1, ref axno1, ref length, param1);

Focas1.ODBPARAIF paraif = new Focas1.ODBPARAIF();

Focas1.cnc_sysinfo(cncHandle,info);

axno = 3;

Focas1.cnc_rdparainfo(cncHandle, 0, 1, paraif);

bool withaxs;

while (paraif.next_no != 0)

{

Focas1.cnc_rdparainfo(cncHandle, paraif.next_no, 1, paraif);

string temp_string = Convert.ToString(paraif.info.info1.prm_type,2);

int temp_type = Convert.ToInt16(temp_string[temp_string.Length - 1]) - 48;

if (temp_string.Length>1)

temp_type = temp_type (Convert.ToInt16(temp_string[temp_string.Length - 2]) - 48)*2;

if (temp_string.Length > 2)

withaxs = Convert.ToInt16(temp_string[temp_string.Length - 3]) == 48;

else

withaxs = false;

if (withaxs)

{

ret = Focas1.cnc_rdparam(cncHandle, paraif.info.info1.prm_no, -1, (short)(4 1 * Focas1.MAX_AXIS), param);//(short)(4 1 * MAX_AXIS)

}

else

{

ret = Focas1.cnc_rdparam(cncHandle, paraif.info.info1.prm_no, -1, (short)(4 1 * Focas1.MAX_AXIS), param1);//(short)(4 1 * MAX_AXIS)

}

}

for (idx = 0; idx < axno; idx )

{

//printf("#%d", idx 1);

//printf("%c\n", param.u.cdatas[idx]);

};

}

private void Form1_Load(object sender, EventArgs e)

{

}

}

}

小贴士

感谢您为本站写下的评论,您的评论对其它用户来说具有重要的参考价值,所以请认真填写。

- 类似“顶”、“沙发”之类没有营养的文字,对勤劳贡献的楼主来说是令人沮丧的反馈信息。

- 相信您也不想看到一排文字/表情墙,所以请不要反馈意义不大的重复字符,也请尽量不要纯表情的回复。

- 提问之前请再仔细看一遍楼主的说明,或许是您遗漏了。

- 请勿到处挖坑绊人、招贴广告。既占空间让人厌烦,又没人会搭理,于人于己都无利。

关于好例子网

本站旨在为广大IT学习爱好者提供一个非营利性互相学习交流分享平台。本站所有资源都可以被免费获取学习研究。本站资源来自网友分享,对搜索内容的合法性不具有预见性、识别性、控制性,仅供学习研究,请务必在下载后24小时内给予删除,不得用于其他任何用途,否则后果自负。基于互联网的特殊性,平台无法对用户传输的作品、信息、内容的权属或合法性、安全性、合规性、真实性、科学性、完整权、有效性等进行实质审查;无论平台是否已进行审查,用户均应自行承担因其传输的作品、信息、内容而可能或已经产生的侵权或权属纠纷等法律责任。本站所有资源不代表本站的观点或立场,基于网友分享,根据中国法律《信息网络传播权保护条例》第二十二与二十三条之规定,若资源存在侵权或相关问题请联系本站客服人员,点此联系我们。关于更多版权及免责申明参见 版权及免责申明

网友评论

我要评论