实例介绍

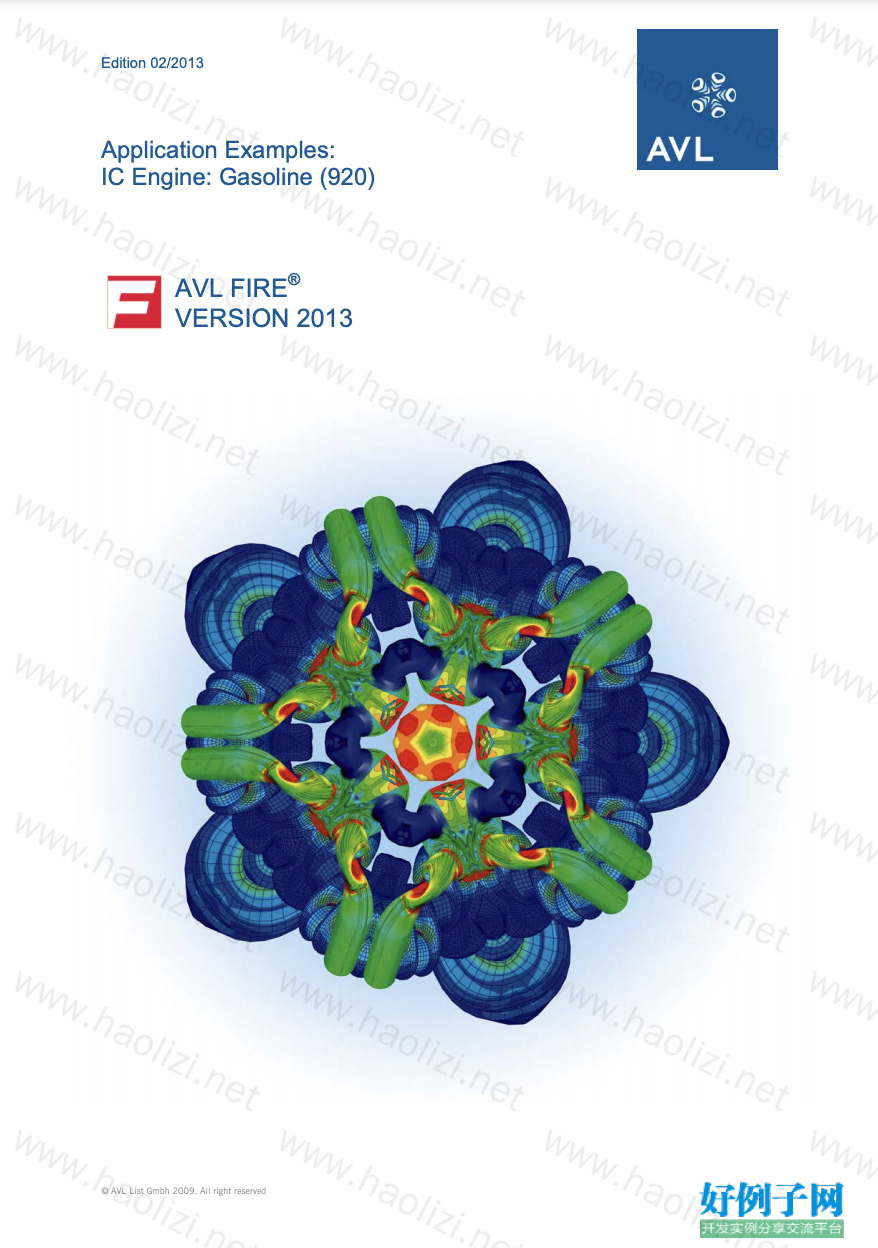

【实例简介】FIRE_920_Gasoline.pdf

【实例截图】

【核心代码】

Table of Contents 1. Introduction _____________________________________________________1-1 1.1. Scope _______________________________________________________________________1-1 1.2. User Qualifications ___________________________________________________________1-1 1.3. Symbols _____________________________________________________________________1-1 1.4. Configurations _______________________________________________________________1-2 2. IC Engine: Gasoline (920) ________________________________________2-1 2.1. Simulation Domain - Overview_________________________________________________2-1 2.2. Meshing Strategy – Overview __________________________________________________2-2 2.2.1. Recommended File Structure on disk _______________________________________2-2 2.2.2. Recommended Workflow___________________________________________________2-2 2.2.3. Selection Naming Conventions: Recommended and Required __________________2-4 2.3. Meshing Procedure – FAME Hexa______________________________________________2-4 2.3.1. Overview ________________________________________________________________2-4 2.3.2. Surface Mesh_____________________________________________________________2-4 2.3.2.1. Import Surface Mesh __________________________________________________2-5 2.3.2.2. Save Project __________________________________________________________2-5 2.3.2.3. Selection Specification _________________________________________________2-5 2.3.3. Edge Mesh _______________________________________________________________2-9 2.3.3.1. Edge Mesh at Valve Region_____________________________________________2-9 2.3.4. Setup FAME Hexa Meshing_______________________________________________2-14 2.3.5. Check Mesh Quality______________________________________________________2-17 2.3.6. Hints to Improve Mesh Quality____________________________________________2-18 2.4. Meshing Procedure - FEP ____________________________________________________2-18 2.4.1. Create New Project ______________________________________________________2-18 2.4.2. Prerequisites – Create Additional Meshes___________________________________2-19 2.4.2.1. Hints for Surface Details ______________________________________________2-20 2.4.2.2. Hints for Closed Valves - Moving Selections _____________________________2-21 2.4.3. Setup FEP Meshing Procedure ____________________________________________2-22 2.4.3.1. How to start FEP? ___________________________________________________2-22 2.4.3.2. Input Surfaces _______________________________________________________2-25 2.4.3.3. Settings _____________________________________________________________2-27 2.4.3.4. Start Meshing _______________________________________________________2-32 2.4.3.5. Results______________________________________________________________2-32 2.4.3.6. Write .fmo – file______________________________________________________2-33 2.5. Solver GUI _________________________________________________________________2-33 2.5.1. Typical Boundary Conditions______________________________________________2-33 2.5.2. Define Data for Calculation _______________________________________________2-34 2.5.2.1. Run Mode ___________________________________________________________2-34 2.5.2.2. Module Activation____________________________________________________2-34 FIRE v2013 IC Engine: Gasoline (920) ii AST.08.0920.2013 – 28-Feb-2013 2.5.2.3. Boundary Conditions _________________________________________________2-35 2.5.2.4. Fluid Properties (Air)_________________________________________________2-38 2.5.2.5. Initial Conditions ____________________________________________________2-38 2.5.2.6. Solver Control _______________________________________________________2-40 2.5.2.7. Output Control ______________________________________________________2-41 2.6. Modules ____________________________________________________________________2-44 2.6.1. Combustion _____________________________________________________________2-44 2.6.1.1. Save Project _________________________________________________________2-44 2.6.2. Start Calculation ________________________________________________________2-44 2.6.3. Monitoring the Calculation _______________________________________________2-44 2.6.3.1. Monitoring the .flb-file________________________________________________2-44 2.6.3.2. Monitoring the .fla-file (Linux Users only) ______________________________2-45 2.6.4. Stopping and Restarting a Calculation _____________________________________2-46 2.7. Post-processing _____________________________________________________________2-46 2.7.1. Load Results ____________________________________________________________2-46 2.7.1.1. Create surface cut and create a movie___________________________________2-46 IC Engine: Gasoline (920) FIRE v2013 AST.08.0920.2013 – 28-Feb-2013 iii List of Figures Figure 2-1: Simulation Domain ...............................................................................................................................2-1 Figure 2-2: Surface Mesh – Worst Case ..................................................................................................................2-3 Figure 2-3: Surface Mesh..........................................................................................................................................2-5 Figure 2-4: Edge Tool – Auto Edge Window.........................................................................................................2-10 Figure 2-5: Surface and Edge Mesh.......................................................................................................................2-10 Figure 2-6: Edge Mesh – Remove Edges ...............................................................................................................2-11 Figure 2-7: Location of Additional Edges .............................................................................................................2-11 Figure 2-8: Create Trajectory.................................................................................................................................2-12 Figure 2-9: Create Edges – Detail Valve Seat Area..............................................................................................2-13 Figure 2-10: Create Edge Mesh - Detail................................................................................................................2-13 Figure 2-11: Edge Mesh – Final State ...................................................................................................................2-14 Figure 2-12: FAME Hexa Volume Mesh – Final State ........................................................................................2-17 Figure 2-13: FAME Hexa Volume Mesh – View Inside Mesh.............................................................................2-17 Figure 2-14: Surface Mesh – Valid from 360 to 581 CA ......................................................................................2-19 Figure 2-15: Surface Mesh – Valid from 581 to 869 CA ......................................................................................2-20 Figure 2-16: Surface Mesh – Valid from 869 to 1080 CA .....................................................................................2-20 Figure 2-17: Cross Section – Valve Gap Area.......................................................................................................2-21 Figure 2-18: Closed Valve – Detail Valve Seat ......................................................................................................2-21 Figure 2-19: Change Valid Range of Surface Mesh..............................................................................................2-22 Figure 2-20: Definition of Axes Direction.............................................................................................................2-23 Figure 2-21: Moving Piston Definition .................................................................................................................2-23 Figure 2-22: Moving Intake Valve Definition.......................................................................................................2-24 Figure 2-23: Moving Exhaust Valve Definition....................................................................................................2-25 Figure 2-24: Add Surface Window.........................................................................................................................2-26 Figure 2-25: Validate Selections Labeling Conflicts............................................................................................2-27 Figure 2-26: Settings Window................................................................................................................................2-28 Figure 2-27: Explanation of Meshing Interval .....................................................................................................2-29 Figure 2-28: Exceptions for BND_Liner Selection.............................................................................................2-30 Figure 2-29: Exceptions for _REF_IN_Seat_3 Selection..................................................................................2-30 Figure 2-30: Exceptions for _REF_EX_Seat_3 Selection..................................................................................2-31 Figure 2-31: Exceptions for _REF_IN_Valves_5 Selection .............................................................................2-31 Figure 2-32: Exceptions for _REF_EX_Valves_5 Selection .............................................................................2-31 Figure 2-33: Exceptions for _REF_Piston Selection.........................................................................................2-31 Figure 2-34: Reinitialization – Input Parameters................................................................................................2-39 Figure 2-35: Formula – Input Parameters............................................................................................................2-42 Figure 2-36: Log Monitoring Window...................................................................................................................2-45 Figure 2-37: Surface cut – Temperature Exemplary at 900 deg. CA..................................................................2-47

好例子网口号:伸出你的我的手 — 分享!

小贴士

感谢您为本站写下的评论,您的评论对其它用户来说具有重要的参考价值,所以请认真填写。

- 类似“顶”、“沙发”之类没有营养的文字,对勤劳贡献的楼主来说是令人沮丧的反馈信息。

- 相信您也不想看到一排文字/表情墙,所以请不要反馈意义不大的重复字符,也请尽量不要纯表情的回复。

- 提问之前请再仔细看一遍楼主的说明,或许是您遗漏了。

- 请勿到处挖坑绊人、招贴广告。既占空间让人厌烦,又没人会搭理,于人于己都无利。

关于好例子网

本站旨在为广大IT学习爱好者提供一个非营利性互相学习交流分享平台。本站所有资源都可以被免费获取学习研究。本站资源来自网友分享,对搜索内容的合法性不具有预见性、识别性、控制性,仅供学习研究,请务必在下载后24小时内给予删除,不得用于其他任何用途,否则后果自负。基于互联网的特殊性,平台无法对用户传输的作品、信息、内容的权属或合法性、安全性、合规性、真实性、科学性、完整权、有效性等进行实质审查;无论平台是否已进行审查,用户均应自行承担因其传输的作品、信息、内容而可能或已经产生的侵权或权属纠纷等法律责任。本站所有资源不代表本站的观点或立场,基于网友分享,根据中国法律《信息网络传播权保护条例》第二十二与二十三条之规定,若资源存在侵权或相关问题请联系本站客服人员,点此联系我们。关于更多版权及免责申明参见 版权及免责申明

网友评论

我要评论